Antecedentes:

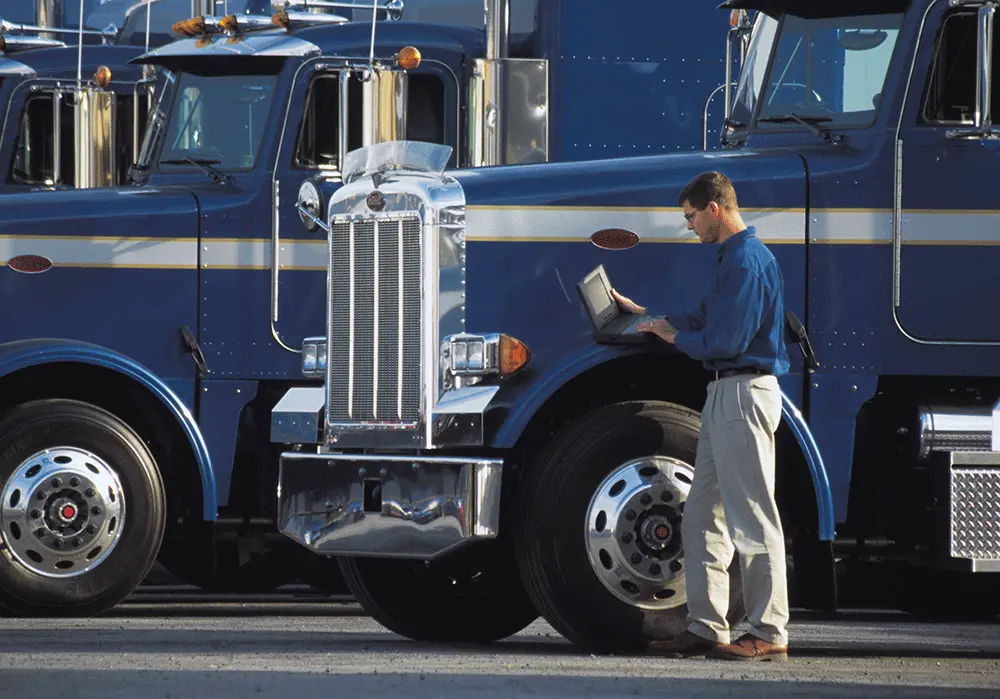

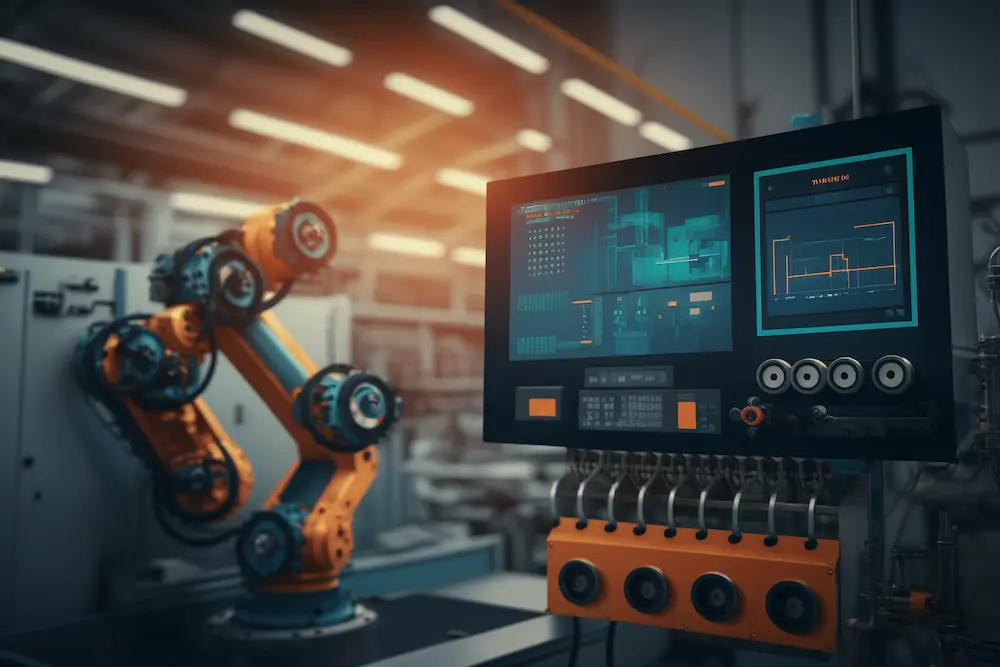

El plan de mantenimiento tradicional del equipo rotativo de un barco requiere que el barco detenga su funcionamiento una vez cada 5 años o, en algunos casos, con más frecuencia durante un mes o incluso más y realice una inspección integral del desmantelamiento del equipo. Los largos períodos de mantenimiento reducen la eficiencia operativa del recipiente. Por lo tanto, la supervisión de la condición con una tecnología no destructiva como el análisis de la vibración, que puede simplificar la inspección de la nave y acortar la ventana de mantenimiento, se ha convertido en la mejor solución para ayudar a los armadores y las empresas de gestión de buques a mantener la competitividad de la industria.

Challenge:

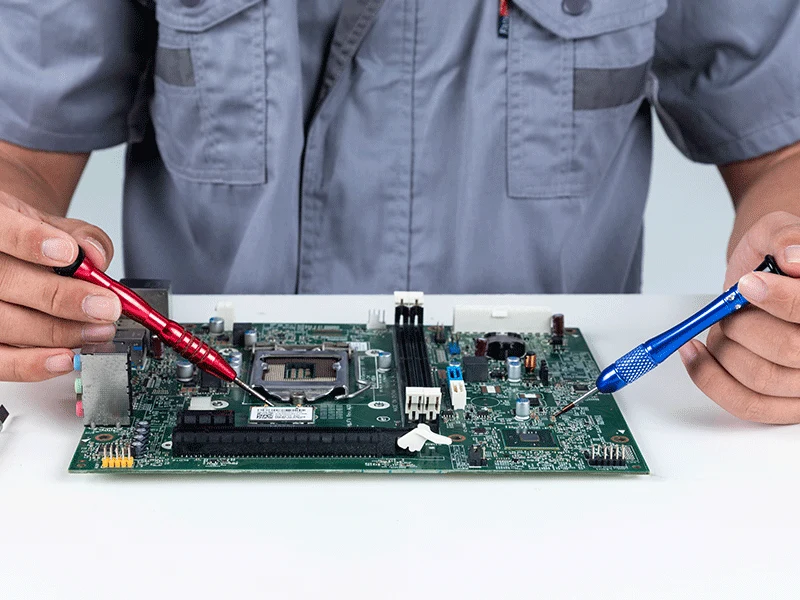

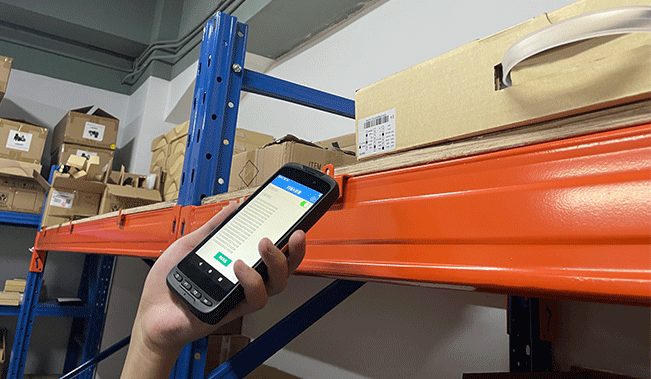

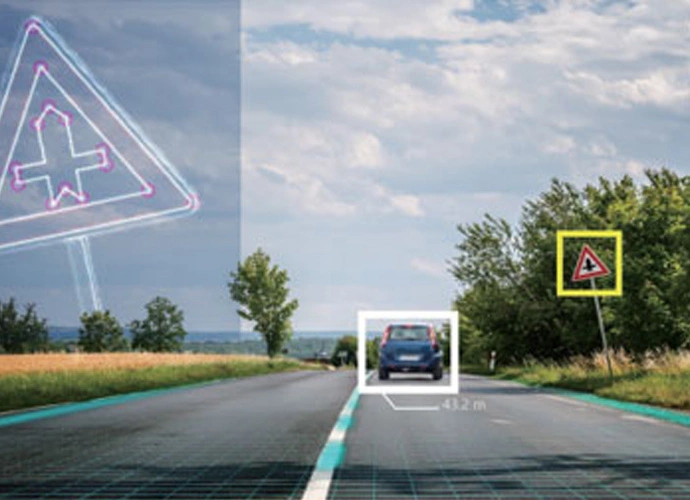

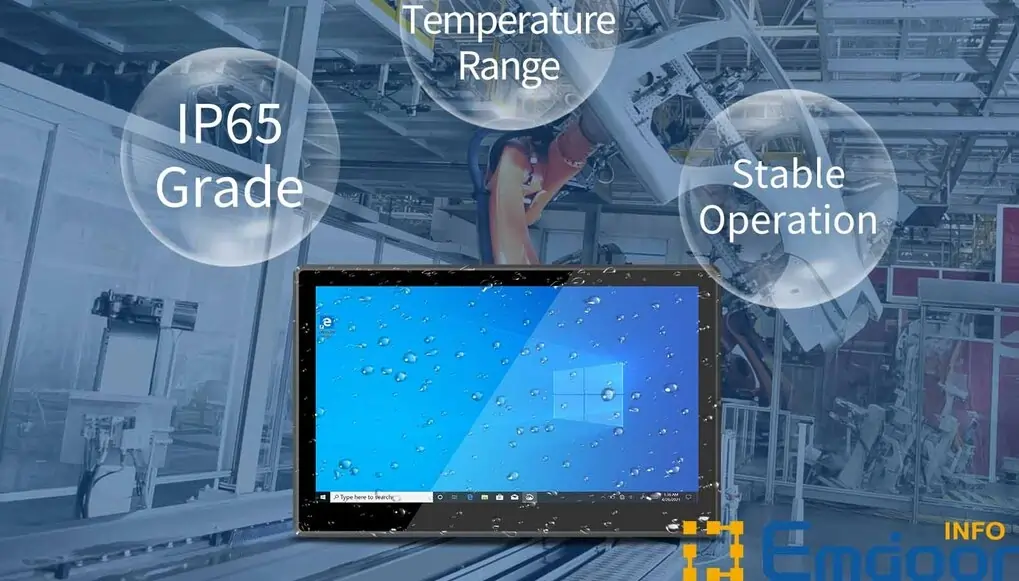

The marine environment is humid and in several geographical locations very warm, and the air is highly corrosive due to salt. Computer equipment for non-destructive testing such as vibration analysis should withstand salt spray corrosion, water mist, and the huge temperature difference between indoors and outdoors to perform daily tasks flawlessly. Furthermore, it also has to cope with the physical shock caused by a ship moving, which cannot be achieved by ordinary computers.

Solution:

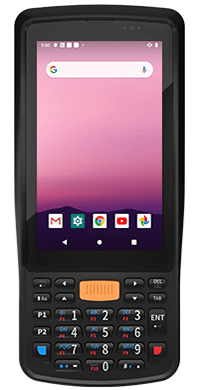

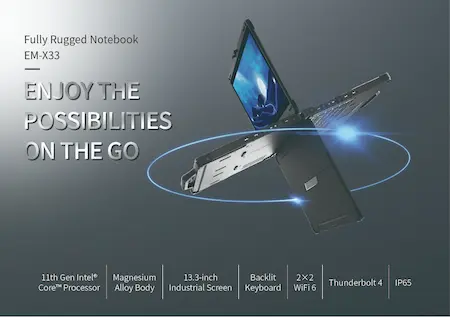

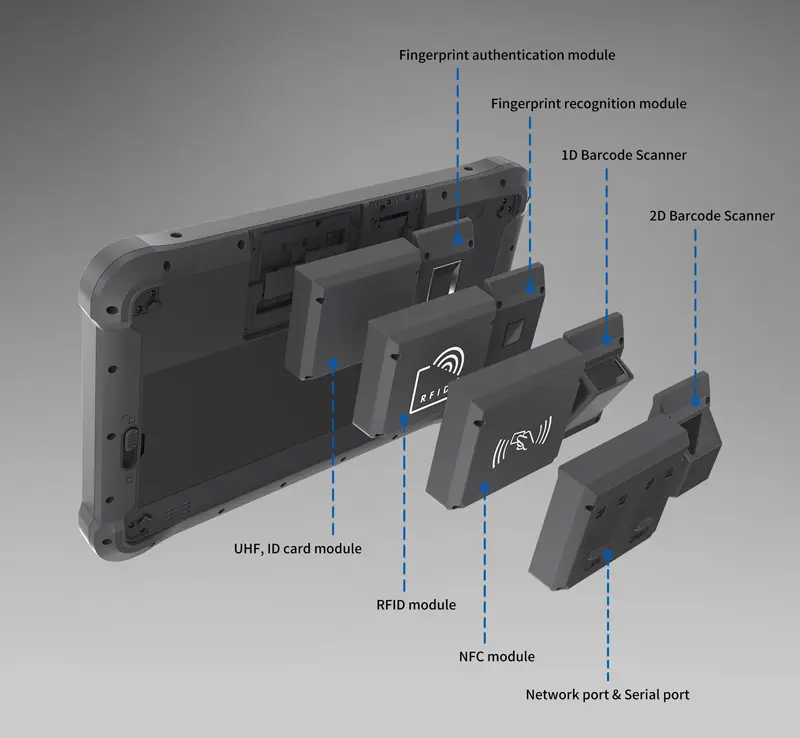

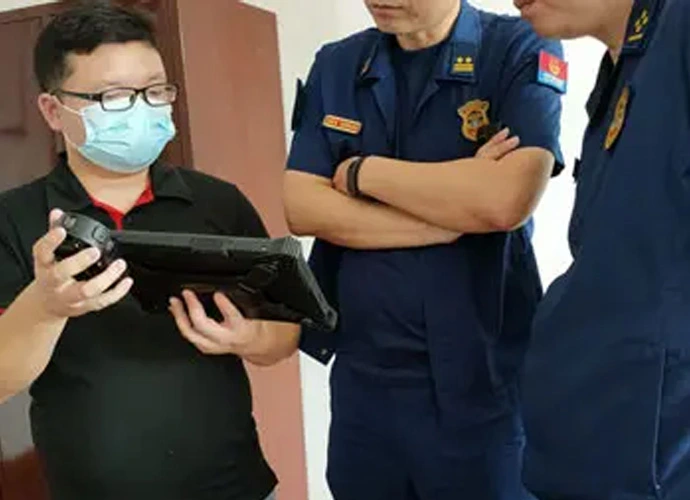

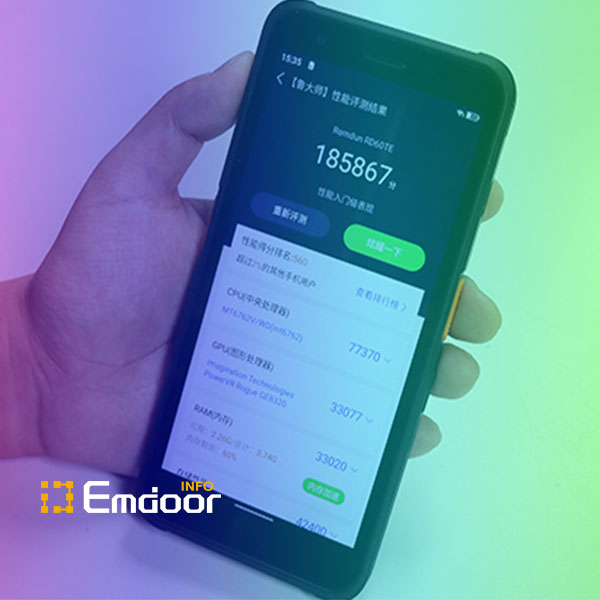

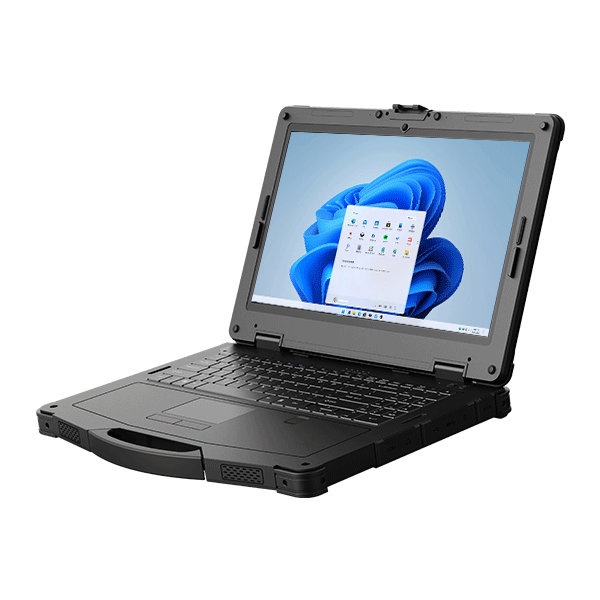

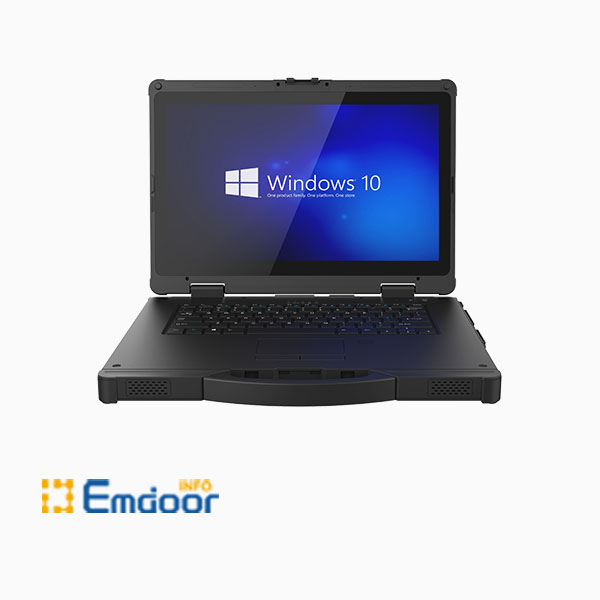

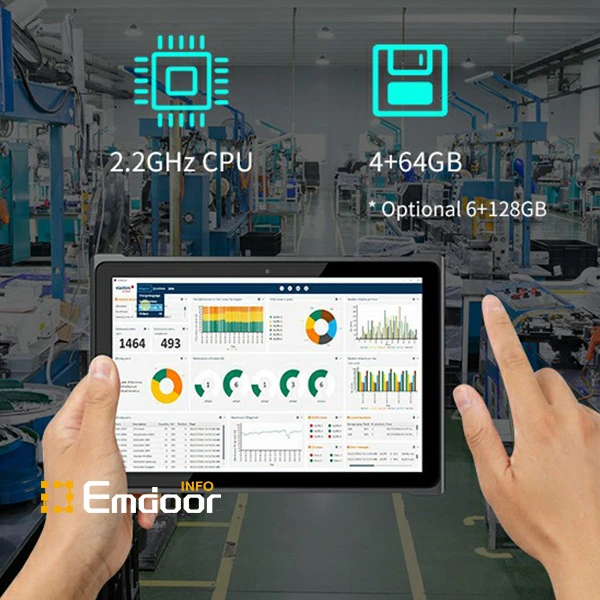

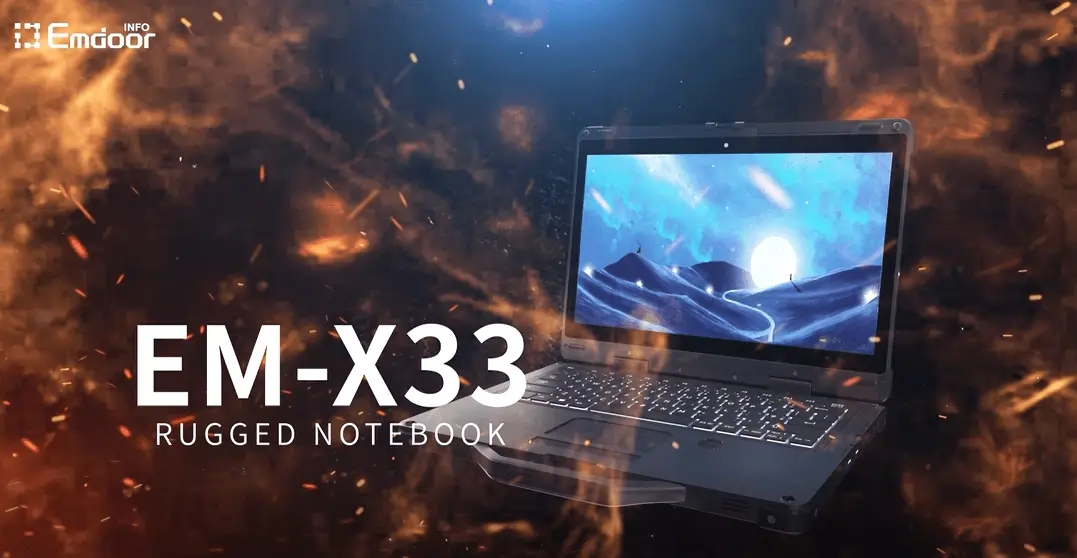

The Emdoor EM-I10J 10-inch rugged tablet windows 10 provides the most cost-effective option for efficient ship inspection, as it has a fully rugged shell, and is salt spray tested, certified to U.S. Military-810G and IP65-rated for water and dust resistance. It’s easy to use in offshore environments where corrosive electronics exist. Another key factor in choosing the I10J tablet is that it has a high-performance Intel quad-core processor that is perfectly compatible with the HAT Analytics 2nd generation digital health monitoring system Ad|Vi|Se, guaranteeing stable diagnostics.

Benefits:

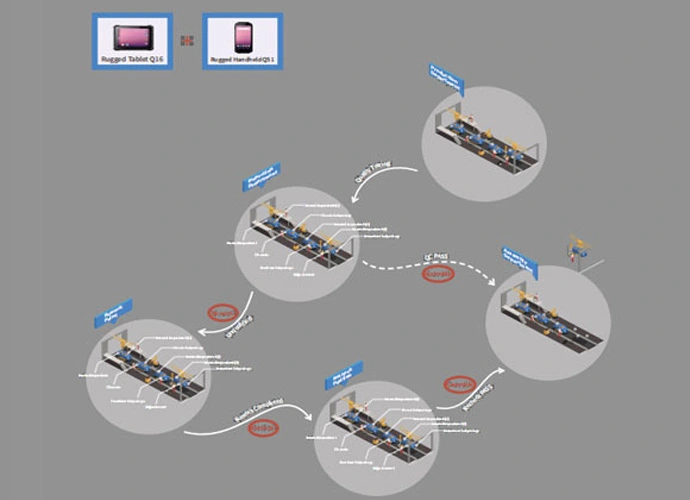

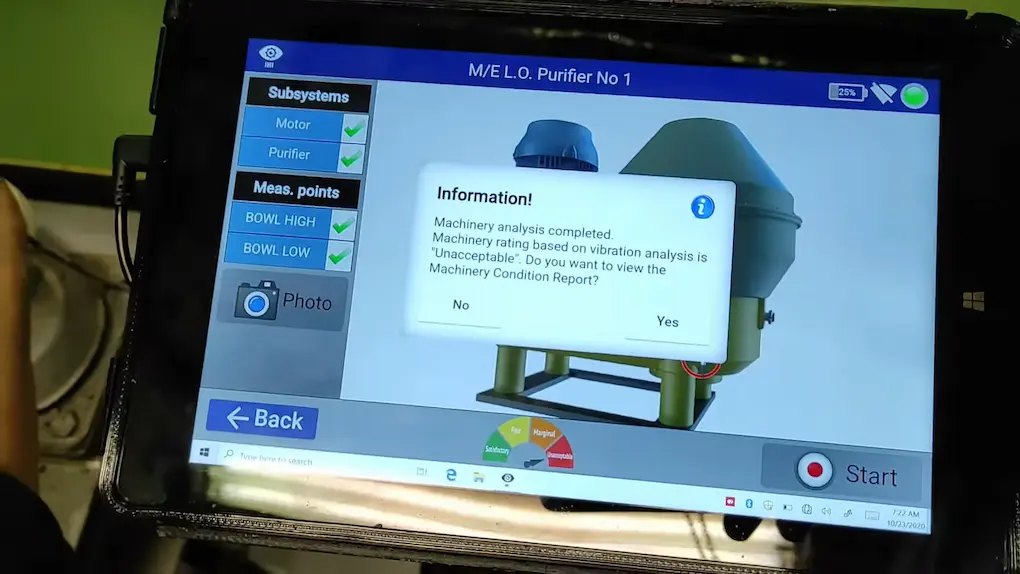

Compared with the traditional maintenance methods, the intelligent ship condition monitoring solution brought by the cooperation of the I10J tablet and the HAT Analytics digital health monitoring system Ad|Vi|Se provides a faster, more effective and reliable predictive ship machinery maintenance mode. Through portable data collection, instant health condition analysis and diagnostics, unplanned downtime and malfunctioning equipment issues are forewarned and repaired, preventing costly and time-consuming catastrophic failure events.

Challenge:

The normal operation of a ship depends on the availability of machinery on board, and regular maintenance is necessary to ensure that the ship is always in good condition. Traditional ship maintenance of the rotating equipment is based on regular openings onboard or in a shipyard, which requires dismantling transportation, and professional inspection. Thus, ships need to go out of business until the maintenance is completed. The workload is large and time-consuming, which increases the pressure on the shipping company. However, predictive maintenance programs can transform maintenance from reactive to proactive, preventing potential failures with early problem detection, increasing equipment lifespan and shortening maintenance windows.

HAT Analytics, a leading provider of predictive maintenance services, delivers innovative digital condition monitoring solutions that require the assistance of rugged mobile computing devices. Because operating offshore, where extreme temperatures, shock, vibration, and salty air are common, overly fragile equipment can add to the high cost of hardware replacement. What mobile computer is their best choice? To find this answer, HAT Analytics conducted an extensive search for data acquisition tablets that meet communication standards and field durability standards.

Solution:

Emdoor's EM-I10J industrial tablet is an ideal choice for HAT Analytics 2nd generation of digital health monitoring system Ad|Vi|Se. As part of the overall solution, its robustness and powerful computing power allow the digital health monitoring system to stably perform real-time monitoring and diagnosis of the ship's mechanical status.

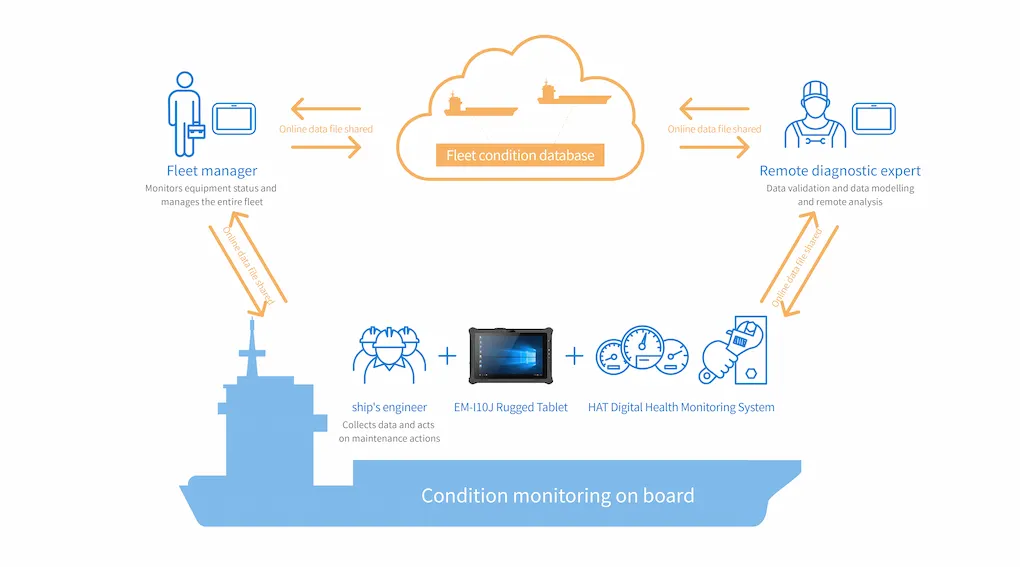

The EM-I10J industrial tablet windows, which operate in cooperation with the HAT Analytics digital health monitoring system Ad|Vi|Se, convert the collected vibration data into an easy-to-understand health report which is presented to the crew via a highly interactive user interface. With the intuitive data display, crews can get measurement results and locate the root cause of the fault faster, and maintenance can be carried out more quickly. Meanwhile, the inspection report will also be automatically generated and transmitted to the cloud server for validation and machine learning modelling through the low-latency network of the EM-I10J tablet. This increases the reliability of the health monitoring system and through the AdViSe CM Dashboard the ship's superintendent and fleet manager can securely access the information and several condition monitoring metrics of the fleet from anywhere. In the face of difficult mechanical problems, the staff can take pictures of abnormal equipment through the EM-I10J high-definition rear camera, and feed them back to the cloud to seek help from remote analysis and diagnosis by the HAT team of experienced engineers.

La tableta EM-I10J resistente cumple con todas las expectativas de HAT Analytics PARA EL Ad | Vi | Se rendimiento y durabilidad del dispositivo, brindando a los técnicos la plataforma estable que necesitan para inspeccionar, depurar y solucionar problemas en una variedad de situaciones, permitiéndoles avanzar en sus tareas de mantenimiento del trabajo.

El entorno marino que implica la exposición a la sal es un gran desafío para los equipos informáticos. Emdoor EM-I10JVentanas de tablet robustasProporciona tecnología anticorrosión única, su diseño de Puerto sellado puede evitar daños en el sistema por pulverización de sal durante el estricto proceso de prueba de pulverización de sal a largo plazo, reducir los costos adicionales causados por fallas de la computadora e interrupciones del trabajo.

El EM-I10J es capaz de trabajar en una amplia gama de temperaturas de-20 a 60 grados Celsius, lo que también es fundamental para los técnicos en alta mar. Debido a que a menudo necesitan trabajar con calor extremo en el mar, luz solar directa y otras condiciones climáticas adversas, el I10J como herramienta auxiliar necesita enfrentar las duras condiciones de trabajo con ellos para brindar un servicio confiable en el sitio.

Las ventajas que el EM-I10JTableta de ventanas robustaOfrecido a los sistemas de 2ª Generación de HAT Analytics no es sólo en su durabilidad sino también en su conexión de red estable. La Transmisión de red de alta calidad del EM-I10J acelera el tiempo que tardan los técnicos de campo en acceder a los datos de diagnóstico y tomar decisiones de diagnóstico a distancia, lo que les permite trabajar con un mayor nivel de eficiencia de campo.

¡Gracias por su atención en Emdoor Rugged PC!

Rellene el formulario para informarnos su necesidad. Nos pondremos en contacto con usted lo antes posible.